-

PLASTIC IN OCEANSRecognizing the huge issue of the of ocean plastic debris and how it affects the marine ecosystem, building on the government strategy to improve waste management sector, our Ocean Bound rPET food grade resin was developed.GET IN TOUCHOcean Bound Plastics

Sourced from 50 kilometers from the shores, collected and processed at bariq’s facility.

Nile QPET ResinSourced directly from the river Nile waters, collected, pressed and processed at bariq’s facility giving a second chance to the bottle.

-

Polyethylene terephthalate

![]() PRODUCT MANUALAPET 70

PRODUCT MANUALAPET 70Our Fiber Grade PET resin, processed with highest quality raw material.

![]() PRODUCT MANUALQFlakes

PRODUCT MANUALQFlakesClear/ Light blue PET Flakes, processed under the latest technology washing line, sourced from our high-quality raw material.

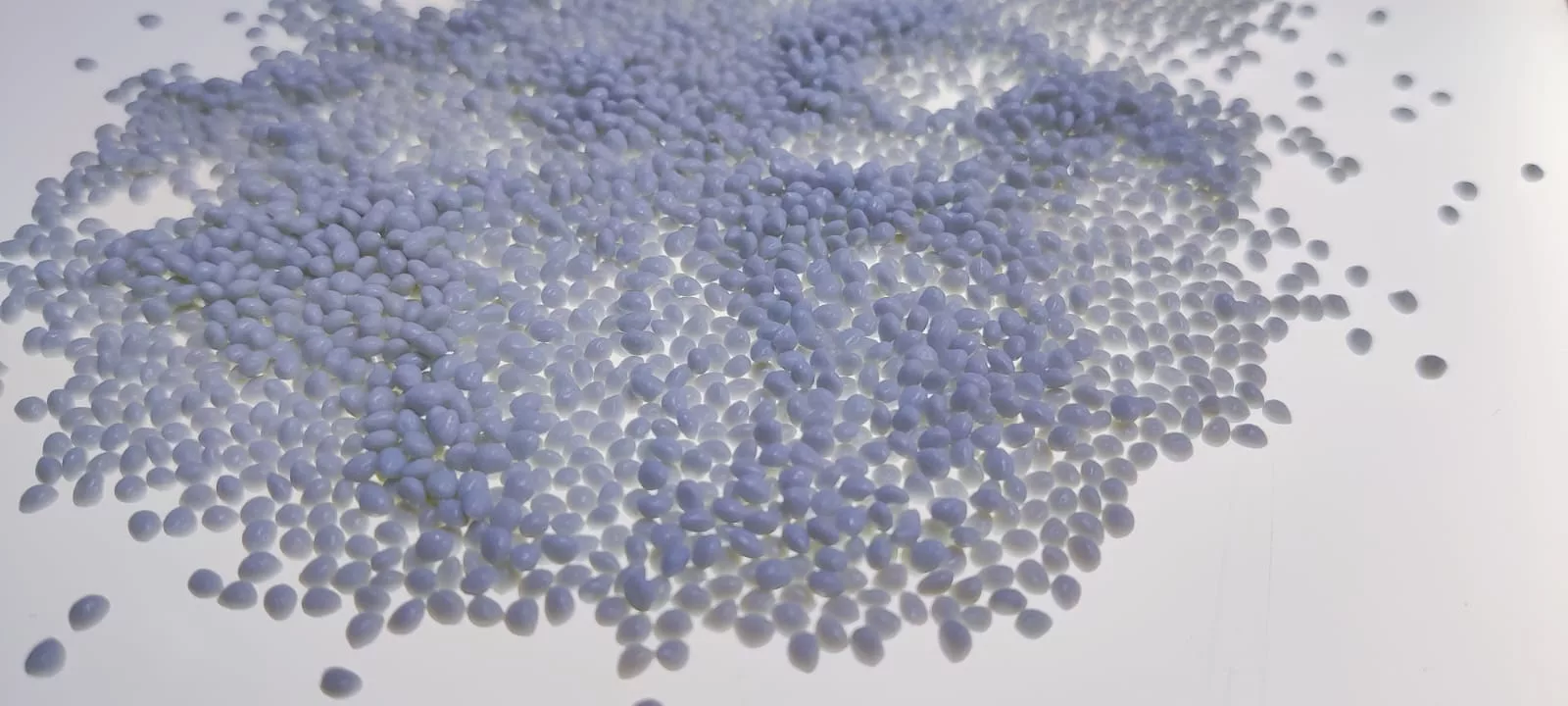

![]() PRODUCT MANUALPET Granulates

PRODUCT MANUALPET GranulatesPelletized blocks, trays, small flakes & ETC to low IV granulates

Polyolefin

![]() PRODUCT MANUALQPO

PRODUCT MANUALQPOOur polyolefin is unique in quality and design, processed under the highest quality standards.